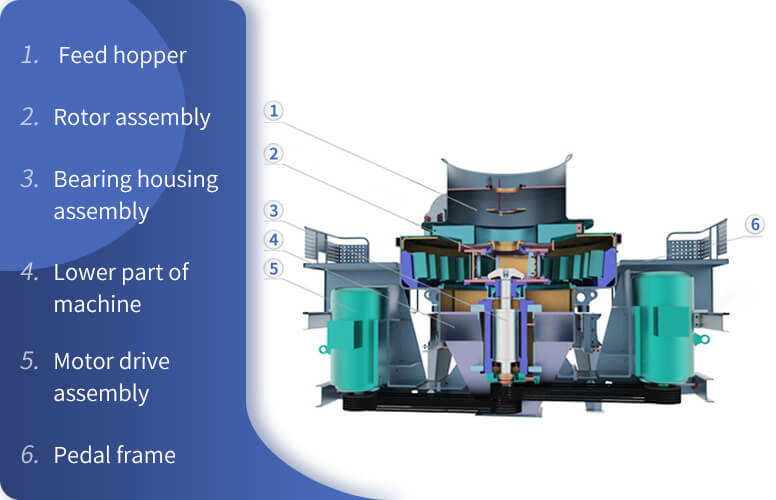

VSI Sand Making Machine Working Principle

Hard stone materials fall into the VSI Sand Making Machine and are divided into two parts. One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.The two parts materials bump and crush fast during the effect of centrifugal force.

Then the materials run like swirl, bump and rub to each other again and again. The finished products go out from the bottom of the machine, and users can get the requested products size after screening by vibrating screen. VSI Sand Making Machine adopts central feeding and central cascade feeding way, which can be changed based on customers’ needs.

Applications of sand making machine

The versatility of the sand making machine makes it useful across many industries. You can find it anywhere high-quality sand or fine aggregate is needed.

Aggregate Production: Creating manufactured sand for concrete, asphalt, and mortar.

Mining: Fine crushing of various ores in the final stages of processing.

Construction Waste Recycling: Turning crushed concrete and brick into usable sand.

Industrial Minerals: Producing fine powders from materials like quartz, dolomite, and silicon carbide.

Artificial sand making: processing river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips, and other materials.

Construction use: construction aggregate, highway road fabric, bedding material, production of asphalt concrete and cement concrete aggregates.

Engineering use: engineering field of water conservancy and hydropower, high-grade roads, highways, high-speed railroads, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise construction of the production of mechanism sand and stone shaping.

Mining industry: fine crushing process in the pre-mill section of the mining industry, material crushing in building materials, metallurgy, chemical industry, mining, refractory materials, cement, grinding materials, and other industries.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."