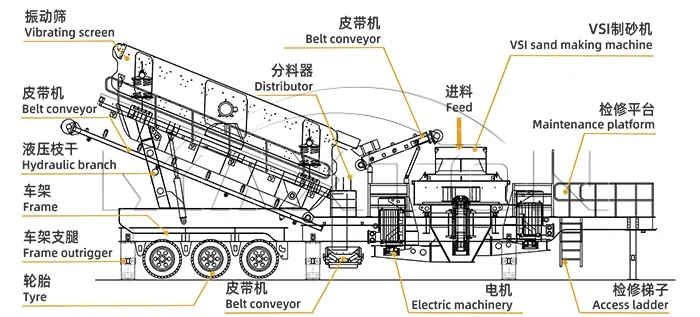

Tyre Mobile Sand-making Machine Working Principle

The mobile sand making machine first sends the raw materials into the crushing chamber through the feeding device. In the crushing chamber, the materials are initially crushed into smaller particles. Subsequently, the crushed material enters the grinding chamber.

Under the action of the high-speed rotating grinding body, the material is further impacted and ground, making its particle size smaller.

Core selling points of Tyre Mobile Sand-making Machine

• Flexible transfer: no fixed infrastructure is required, and the crawler/tire design is suitable for complex terrains such as mines and construction waste dumps.

• Sand and gravel are produced at the same time: a single machine can simultaneously produce 0-5mm sand and 5-10mm gravel, reducing equipment investment.

• Grain shape optimization: VSI sand making machine has good roundness and excellent grading of finished sand, which can replace natural sand.

• Environmental protection and energy saving: closed design + pulse dust removal, low noise and dust pollution.

• Intelligent control: PLC system adjusts parameters in real time, with low failure rate.

Applicable stone types

Mobile sand making machine is suitable for processing medium and high hardness stones, such as:

• Pebbles, river pebbles (rounded particles, need VSI impact crushing)

• Granite, basalt (high hardness, need cone crusher + sand making machine combination)

• Limestone, construction waste (medium hardness, can be crushed by impact or impact)

• Tailings, coal gangue (environmentally friendly recycling)

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."