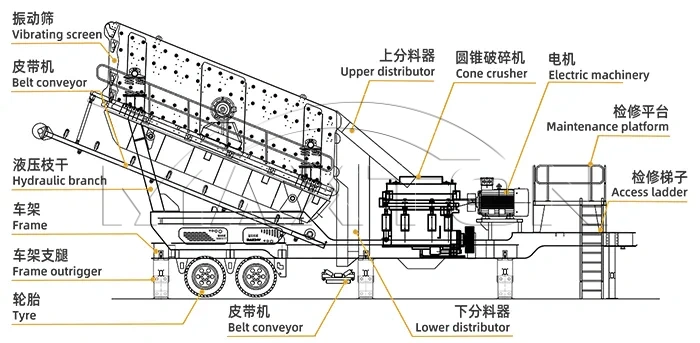

Tyre Mobile Cone Crushing Plant Working Principle

Feed the material through feeder to cone crusher in regular way. After primary crushing, the material enters closed crushing circuit through inclined vibrating screen. The crushed material is conveyed out by the belt conveyor, and to be crushed continually.

Tyre Mobile Cone Crushing Plant can remove inclined vibrating screen according to practical producing environment, and crush the material directly, in order to work together with other crushing equipment in a convenient and flexible way.

Features of Tyre Mobile Cone Crushing Plant

Equipped with hydraulic cone crusher made by MAXTON, Tyre Mobile Cone Crushing Plant can produce aggregate of 10-45mm.Its arrangement device is installed laterally and is effected in closed and hydraulic way.

It allows the arranging operation easier and faster. The arrangement can be realized via control box, which makes the system more suitable to arrange discharging opening in regular time.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."