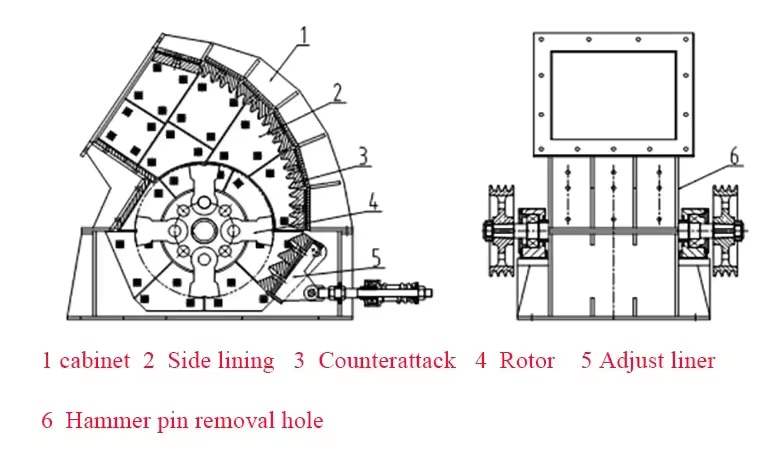

PCZ Heavy Hammer Crusher Working Principle

The PCZ Heavy Hammer Crusher mainly relies on impact energy to complete the crushing operation of materials. When the hammer crusher is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher chamber evenly. The high-speed rotating hammer head rushes towards the baffle plate and the sieve bar in the frame, and the material larger than the sieve hole size is retained on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size.

Performance Advantages

1.Large feed size: The feed particle size can reach 1600mm, the crushing ratio is high, and the output can reach 3000 tons per hour.

2.Low cost: With powerful crushing force and the ability to achieve one-step shaping, this equipment eliminates the need for secondary crushing and shaping processes, reducing crushers procurement costs.

3.Alloy composite hammer: The Low alloy steel hammer head has longer service life Less wear and tear. Wear-resistant hammer head can reduce downtime and ensure production efficiency.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."