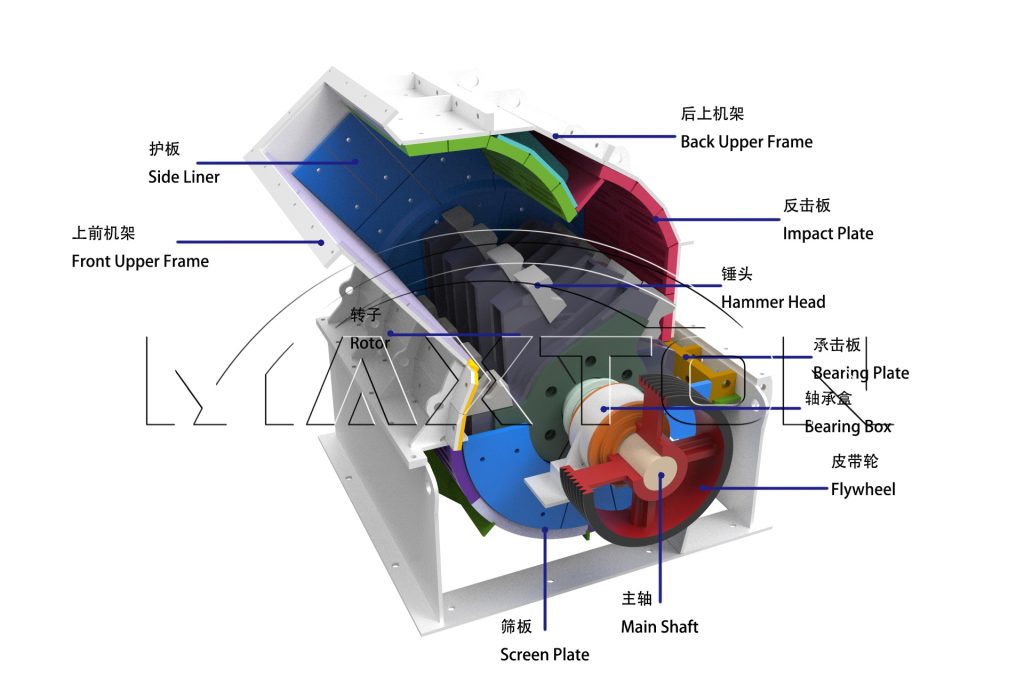

PC Hammer Crusher Working Principle

The main working part of the PC Hammer Crusher is a rotor with a hammer (also known as a hammer head). The rotor consists of the main shaft, a disc, a pin, and a hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing, and grinding action of the high-speed moving hammer.

In the lower part of the rotor, there is a sieve plate, and the particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, and the coarse particles larger than the sieve hole size remain on the sieve plate and continue to be hit and ground by the hammer, and finally pass through the sieve plate Exhaust from the machine.

Performance Advantages

1.The hammers are made of new wear-resistant alloy material and casted by new technology which has good wear resistance and impact resistance.

2.The rotor of this hammer crusher features a great inertia and high rotating speed, and the linear velocity of the hammer reaches 30~35m/s.

3.The product size can be adjusted by variety of the grizzly bars and screens in order to meet different product demands.

4.Due to its large feeding size design, a variety of minerals can be fed into hammer crusher.

5.The mechanical structure of the hammer crusher is simple, it is easy to replace the hammers.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."