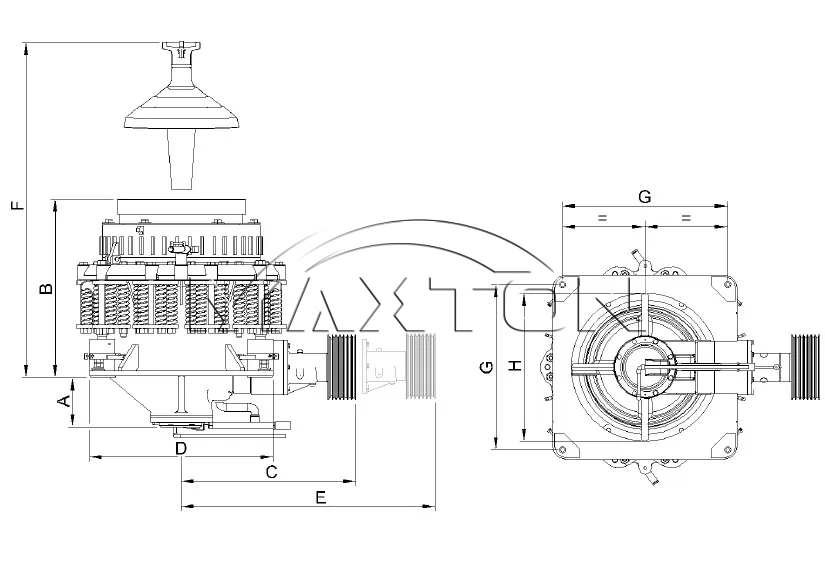

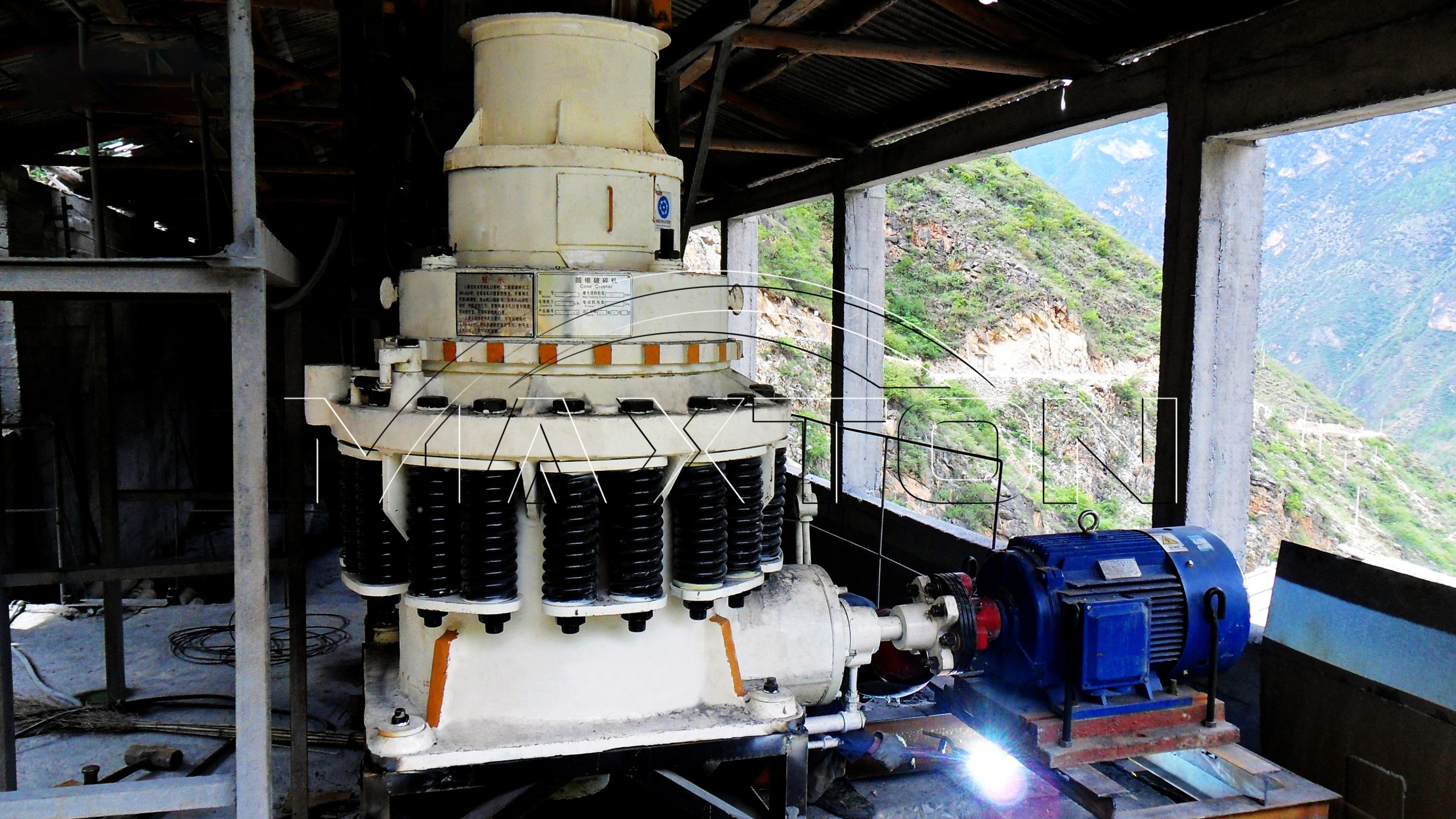

CS Symons Cone Crusher Working Principle

CS Symons Cone Crusher is a compression type of stone crusher. The feeding rock is crushed by squeezing or compressing the feed material between a wear resistant mantle and a manganese concave or a bowl liner. The mantle is a moving part that gyrates in an eccentric motion though an eccentrically gyrating spindle.

When rock enters the top of the cone crusher, it is squeezed between the mantle and the bowl liner or concave, as the eccentric spindle rotates to cause the compression within the chamber. The material gets smaller as it moves down through the wear liner as the opening in the cavity gets tighter. Large pieces of ore are broken once, and then fall to a lower position where they are broken again. This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point.

The CS Symons Cone Crusher is adjusted by spinning the bowl up or down manually or through hydraulic rams. A series of powerful springs give the necessary tramp protection without damage to the crusher.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."