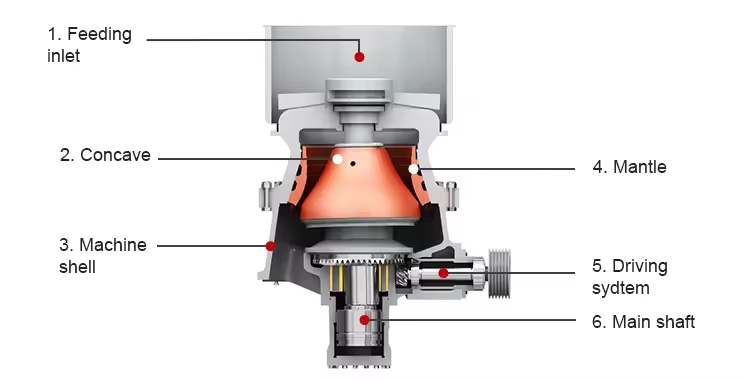

CS/CH Single-Cylinder Hydraulic Cone Crusher Working Principle

The CS/CH Single-Cylinder Hydraulic Cone Crusher adopts the principle of laminated crushing. The motor drives the eccentric sleeve to rotate, driving the moving cone to do a pendulum motion, so that the material is squeezed, impacted and sheared in the crushing chamber to achieve continuous crushing.

Its core control is completed by the hydraulic system, mainly including:

• Hydraulic adjustment of the discharge port: By adjusting the pressure of the hydraulic cylinder, the position of the moving cone is accurately controlled, the crushing gap is changed, and the discharge of different particle sizes is achieved.

• Hydraulic over-iron protection: When unbreakable objects (such as iron blocks) enter the cavity, the hydraulic system automatically releases pressure, and the moving cone quickly descends to discharge foreign objects to avoid equipment damage.

• Hydraulic cavity clearing function: When the CS/CH Single-Cylinder Hydraulic Cone Crusher is shut down, the hydraulic system can be operated with one button to lift the moving cone, quickly clear the blocked materials, and reduce manual maintenance time.

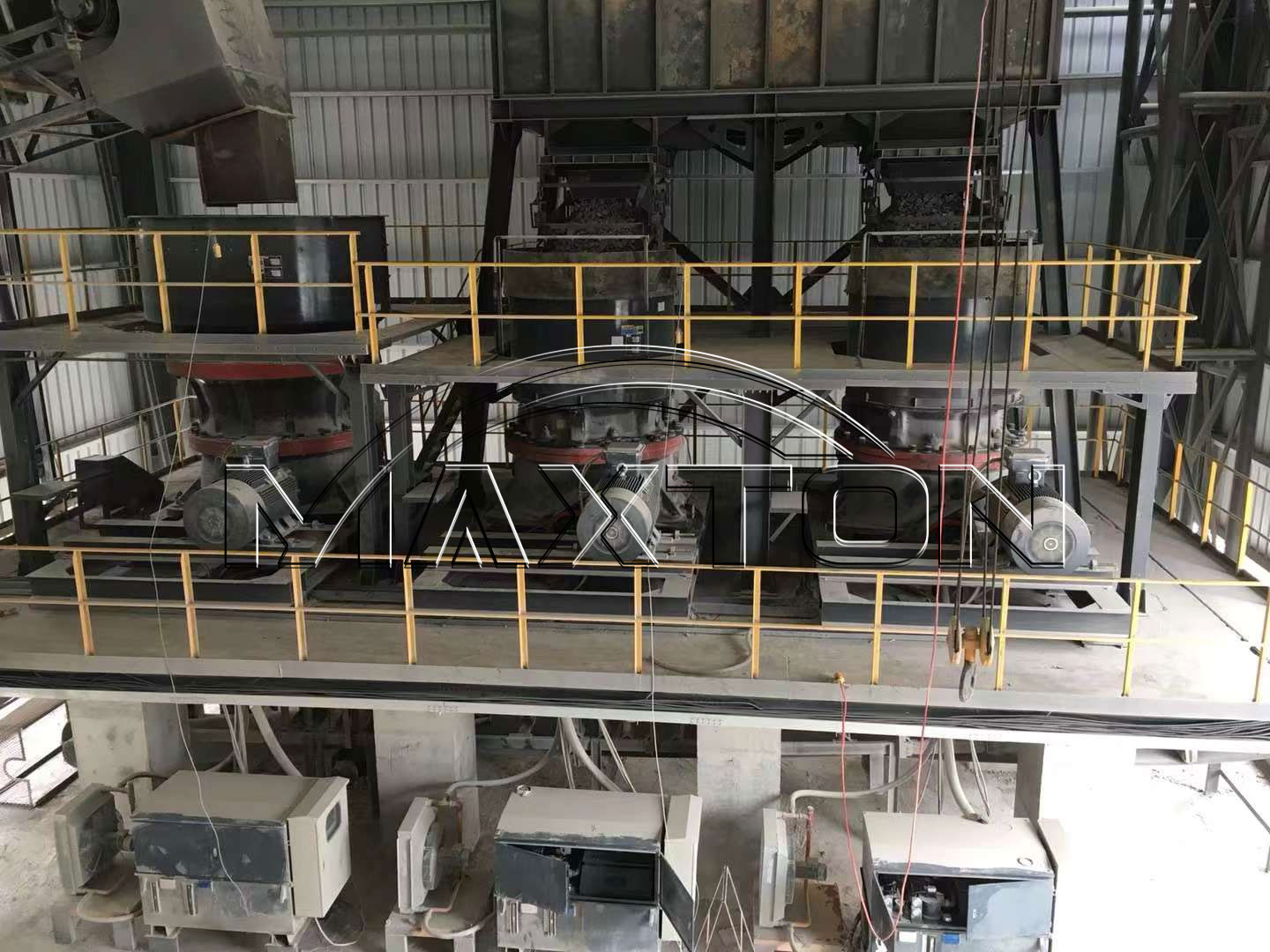

Performance Advantages

1. High efficiency: The lamination crushing principle makes the material particle shape better, the qualified rate is increased by 20%-30%, and the energy consumption is 15%-20% lower than that of the spring cone crusher.

2. Convenient maintenance: The hydraulic system replaces the traditional spring structure, simplifies the adjustment and cavity cleaning operations, and reduces the maintenance time by more than 50%.

3. Long-life design: Key components such as the main shaft adopt forging technology, and the liner uses high manganese steel or composite alloy, with a life of up to 8000-12000 hours.

4. Environmental protection and low noise: closed dust-proof design, with dust removal device, the noise is less than 75dB, meeting environmental protection requirements.

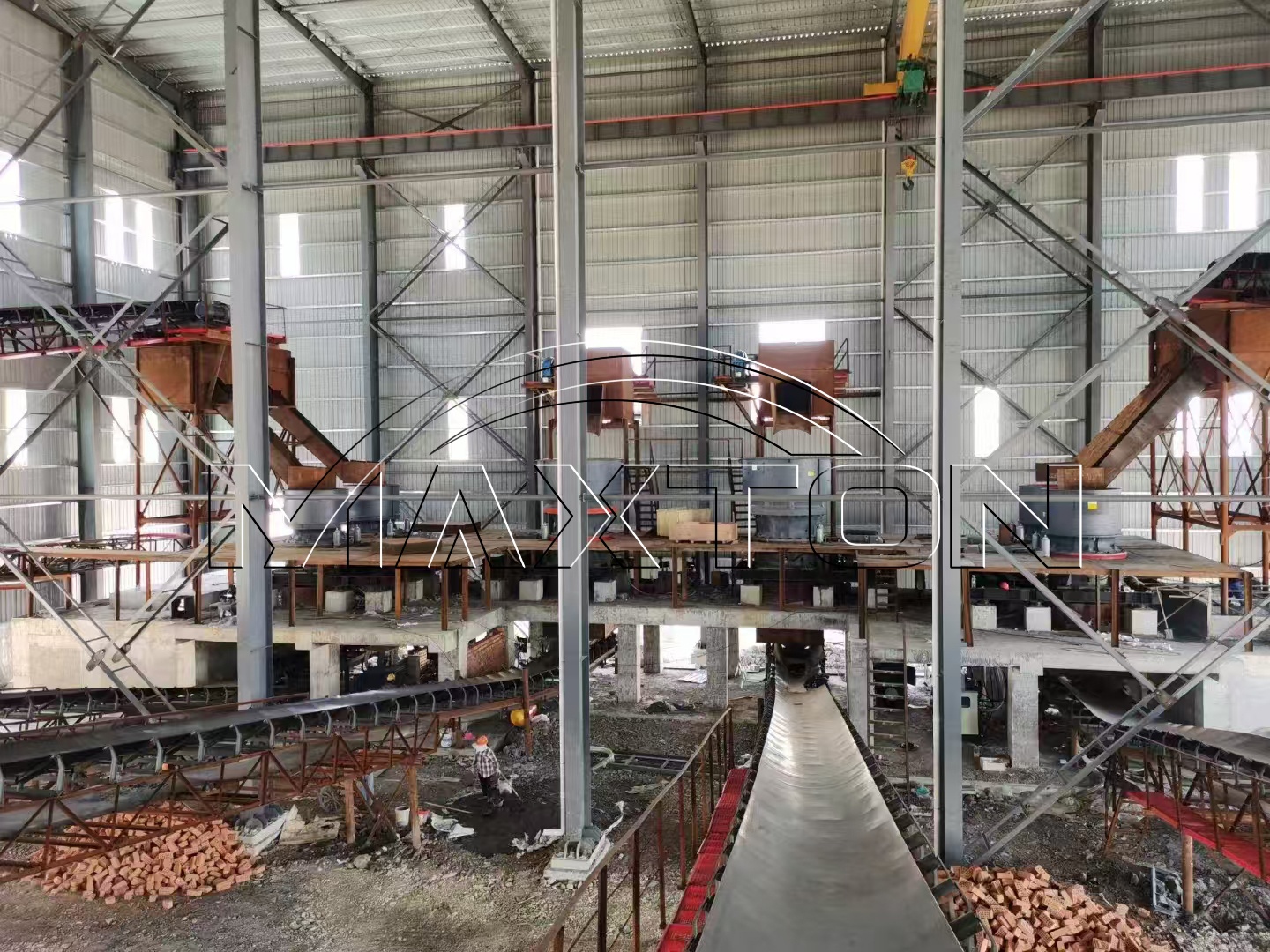

Typical Application Scenarios

• Mining: Crushing iron ore, copper ore, granite, etc., feed size ≤560mm, processing capacity 50-1500t/h.

• Aggregate production: used for machine-made sand and high-quality gravel processing, the finished product size can be adjusted to 3-30mm.

• Metallurgical slag processing: finely crush steel slag and furnace slag to recover metal resources.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."