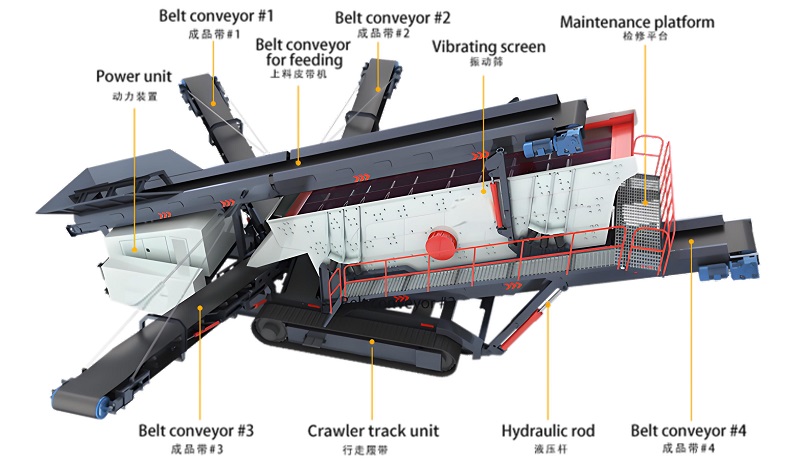

Crawler Mobile Screening Station Working Principle

Crawler Mobile Screening Station effectively meets the screening requirements of different materials by adjusting the screening angle, amplitude, and vibration intensity. This equipment boasts high screening efficiency and large output, suitable for various screening operations such as heavy screening, medium screening, and fine screening.

Crawler Mobile Screening Station is widely used in mining, coal, building materials, sand and gravel, metallurgy, and chemical industries. Depending on the different particle sizes and materials of the finished product, we can provide customers with Crawler Mobile Screening Station in various screen surfaces, models, and applications.

Core advantages of crawler mobile screening station

1. Efficient screening: Multi-layer vibrating screen design (2-4 layers optional), screening efficiency increased by 30%, processing capacity of 50-500t/h, adapting to the grading needs of materials with different particle sizes (0-100mm).

2. Intelligent control: PLC+touch screen integrated system, real-time monitoring of screen status, vibration frequency, conveyor belt speed, support one-button start and stop, fault self-checking.

3. Environmental protection and low consumption: Optional closed dust removal system (dust suppression efficiency ≥ 95%) and noise reduction module to meet environmental emission standards and reduce operational pollution.

4. Flexible transfer: Modular design, hydraulic folding structure, complete transportation status switching within 15 minutes, adapt to frequent mobile operation needs.

Applicable scenarios of the crawler mobile screening station

• Mine aggregate grading: Accurately separate finished materials of multiple specifications, such as 0-5mm, 5-10mm, 10-20mm, etc.

• Construction waste recycling: Screening of steel bars, wood, and concrete blocks to improve the purity of recycled aggregates

• Road construction: On-site screening of roadbed materials to reduce material transportation costs

• Pre-screening in sand and gravel plants: Pre-screening of over-limit particles to improve back-end crushing efficiency

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."