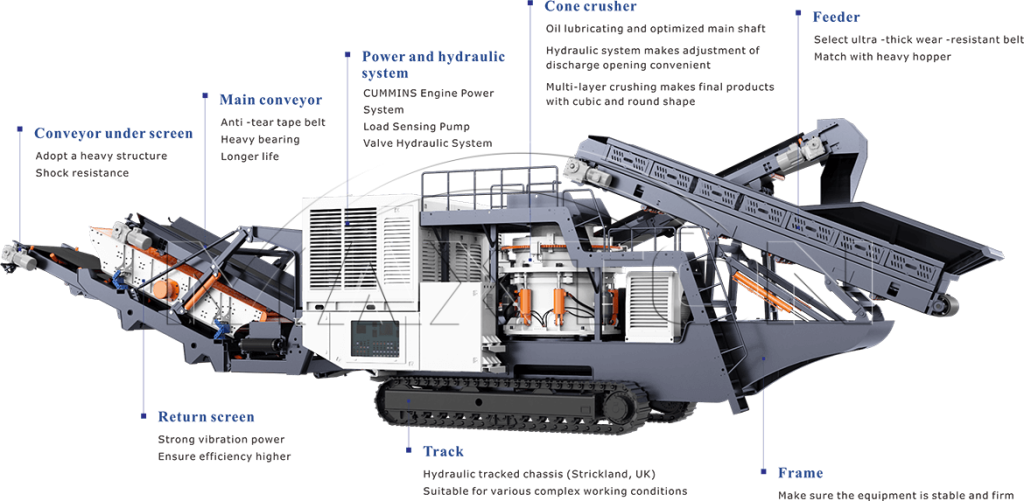

Crawler Mobile Cone Crusher Working Principle

The crawler-type cone mobile crusher uses a high-performance cone crusher as the core and is equipped with a heavy-duty crawler chassis system. It can achieve 360° free transfer operation under complex working conditions such as mining, aggregate processing, and urban building demolition.

Core components

• Cone crusher: adopts the principle of lamination crushing, suitable for medium and high hardness materials (such as granite, basalt), with excellent finished product shape and stable gradation.

• Crawler chassis: hydraulic drive, remote control operation, adaptable to complex terrain (slope up to 15°), no trailer required for transfer.

• Feeding system: pre-screening of vibrating feeder to reduce over-crushing.

• Control system: PLC intelligent control, optional remote monitoring, real-time adjustment of parameters (discharge port, speed, etc.).

Outstanding Advantages Of Crawler Crawler Mobile Cone Crusher

Crawler Mobile Cone Crusher is a mobile device that integrates cone crusher and crawler walking, suitable for mining, construction waste recycling and other scenes, with a processing capacity of 50-400 tons/hour, remote intelligent control, and flexible transfer.

• Mobility: No infrastructure is required, it can be operated upon arrival at the site, saving time and transportation costs.

• Versatility: It can be matched with cone crushers of different chamber types (such as standard type, short head type) to meet the needs of coarse or fine crushing.

• Environmental protection and energy saving: Some models are equipped with noise reduction system and spray dust suppression device, which meets environmental protection requirements.

• High automation: Over-iron protection and automatic cavity cleaning function reduce the risk of downtime.

Typical application scenarios

• Mining: Crushing ore directly on site to reduce the transportation cost of raw ore.

• Construction waste recycling: Mobile processing of concrete, bricks and tiles to produce recycled aggregates.

• Sand and gravel aggregate production: Matching with mobile screening station to form a flexible production line.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."