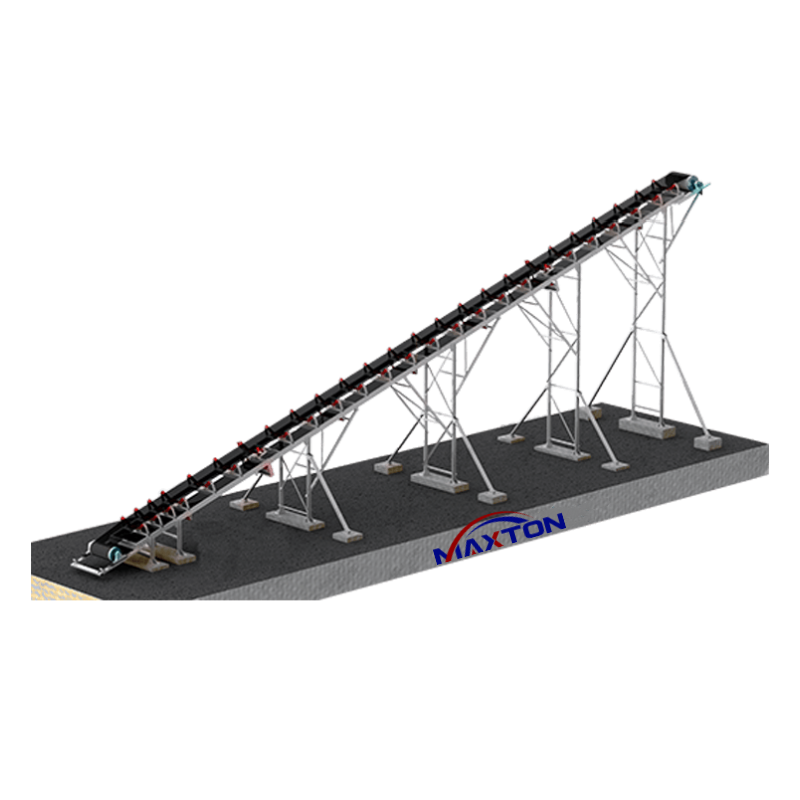

Belt Conveyor

In industry, belt conveyor acts as connections between different equipment to realize continuous and automatic production, which can improve efficiency and reduce labor intensity.

Are you interested in our machines? Custom Solution for your needs.Contact Us.

Belt Conveyor Details

- DATE

- APPLICATION FIELD

- Reviews (3)

*The capacity and output will vary according to different materials, feed particle size, and other factors. Please contact MAXTON for equipment selection for specific projects.

| Model | Belt Width (mm) | Conveying length(m) / Power(kw) | Conveying speed (m/s) | Conveying amount (t/h) | ||

| B500 | 500 | ≤10 / 3 | 12-15 / 4-5.5 | 15-30 / 5.5-7.5 | 1.25-2.0 | 40-80 |

| B650 | 650 | ≤10 / 4 | 12-15 / 7.5 | 15-30 / 7.5-11 | 1.25-2.0 | 80-120 |

| B800 | 800 | ≤10 / 4 | 12-15 / 7.5 | 15-30 / 7.5-15 | 1.25-2.0 | 120-200 |

| B1000 | 1000 | ≤10 / 5.5 | 10-20 / 7.5-11 | 20-40 / 11-22 | 1.25-2.0 | 200-320 |

| B1200 | 1200 | ≤10 / 7.5 | 10-20 / 7.5-15 | 20-40 / 15-30 | 1.25-2.0 | 290-480 |

| B1400 | 1400 | ≤10 / 11 | 10-20 / 15-22 | 20-40 / 22-45 | 1.25-2.0 | 400-680 |

| B1600 | 1600 | ≤10 / 15 | 10-20 / 22-30 | 20-50 / 30-75 | 1.25-2.0 | 600-1080 |

| B1800 | 1800 | ≤10 / 18.5 | 10-20 / 30-45 | 20-50 / 45-110 | 1.0-2.0 | 800-1500 |

| B2000 | 2000 | ≤10 / 22 | 10-20 / 45-55 | 20-50 / 55-132 | 1.0-2.0 | 1000-2000 |

| B2400 | 2400 | ≤10 / 30 | 10-20 / 55-75 | 20-50 / 75-185 | 1.0-2.0 | 1500-3000 |

Note:

1. The conveying capacity in the table is obtained under the conditions of material density of 1.0t/m3-1.6t/m3, conveyor inclination angle ≤18°, and material stacking angle of 30°.

2. The density of the conveyable material is below 2.5t/m2.

3. The conveying length is not limited to the values listed in the table and can be manufactured according to user needs.

Maximino

From Saudi Arabia

"MAXTON mining equipment revolutionized our Saudi copper mine – handling 50°C desert heat without performance drops. The Arabic-speaking engineering team provided on-site training that cut our ramp-up time by 65%.After 18 months, their durable grinding mill show zero wear in our abrasive conditions. We consider MAXTON is a reliable partner for GCC mining projects. Would recommend them for friend."

Alexander

From Indonesia

"MAXTON has multiple projects in our area. I visited two of them, which gave me greater confidence in handing them over to us. Ultimately, our company purchased a MAXTON grinding mill production line, and the project passed inspection on the first try."

Jason

From USA

"After switching to MAXTON mining equipment, our productivity jumped 40% with half the maintenance costs. The German-engineered hydraulic system outperforms competitors in hard rock conditions.What truly impressed us was their 24/7 remote troubleshooting – a game-changer for our Denver iron ore site. Three years of zero unplanned downtime proves MAXTON’s ‘Built for Decades’ promise."