SOLUTION

80-100 tons/hour hard stone crusher production line

Processing Overview

80-100 tons/hour hard stone crusher production line Introduction

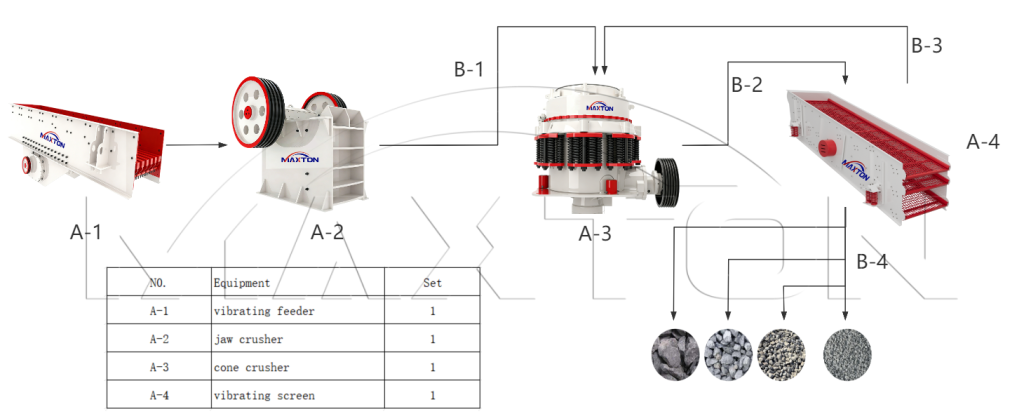

The core configuration of the 100 tons/hour hard stone crusher production line includes a hopper, a ZSW850×3000 vibrating feeder, a PE500×750 jaw crusher, a PYB900 or CS75 cone crusher (secondary crushing equipment is optional), a vibrating screen, and a belt conveyor.

This stone crushing plant can professionally crush and process hard raw materials such as limestone, granite, and andesite, producing a variety of products including coarse aggregate, crushed stone, rock sand, and fine aggregate. Coarse aggregate is mainly used in the preparation of ready-mixed concrete and asphalt concrete; crushed stone is suitable for road base and subbase paving projects; and fine aggregate can be used in concrete pouring and plastering material production.

Core Features of the 80-100 tons/hour hard stone crusher production line

1. Two-stage crushing process architecture: Based on the required output precision, coarse crushing equipment and secondary crushing equipment can be scientifically matched, ensuring an efficient and orderly crushing process that guarantees the material is refined to the preset technical standards at each stage.

2. Wide Range of Raw Material Compatibility: It can process various hard rocks and ores such as limestone, granite, basalt, river pebbles, marble, and iron ore. The resulting products are widely used in various civil engineering projects, including hydropower, building construction, highway construction, railway laying, and airport runway construction.

3. Precise and Controllable Finished Product Specifications: The standard output particle sizes are 0-6 mm, 6-12 mm, and 12-25 mm (corresponding to inch specifications: 0-1/4 inch, 1/4 inch-1/2 inch, 1/2 inch-1 inch). Other particle sizes can also be customized according to customer needs. The quality of the finished aggregate meets relevant standards for building aggregates and is suitable for multiple fields such as hydropower projects, highway construction, and urban infrastructure construction.

4. Flexible Capacity Customization: In addition to this specification, MAXTON also offers customized design services for stone crushing production lines with capacities ranging from 100 tons/hour to 1000 tons/hour (including 150 tons/hour, 200 tons/hour, 300 tons/hour, etc.). We can design a customized solution for you free of charge, including a production flow chart and detailed quotation, precisely matching your production needs.

5. Significant Overall Operational Benefits: It boasts core advantages of high production efficiency and low operating costs. The finished aggregate has uniform particle size and regular shape, and dust emissions strictly comply with relevant environmental protection standards. Relying on an advanced control system, it can ensure the safe, stable, and continuous operation of the production line throughout the entire process, improving overall production efficiency.

How Does Hard Stone Crusher Plant Work?

1. Raw Material Pre-treatment and Conveying: Medium-to-high hardness raw stones are fed uniformly into the jaw crusher via a vibrating feeder. A model with a bar screen can be selected to pre-separate impurities and reduce equipment load.

2. Secondary Crushing: After coarse crushing in the jaw crusher, the raw materials are transferred to the secondary crushing unit by a belt conveyor. Depending on the hardness of the raw materials and the requirements of the finished product, equipment such as a cone crusher can be selected for secondary refinement.

3. Screening: The crushed material is graded according to a preset particle size using a vibrating screen. Qualified finished products are sent to the stockpile for sale; substandard materials are returned to the secondary crusher for recycling, ensuring quality.

4. Finished Product Customization and Environmental Protection: Finished product particle size can be customized according to your requirements, and dust removal devices can be added to ensure emissions meet standards.