SOLUTION

40-60 tph Stone Crushing Plant

Processing Overview

40-60 Tons/Hour Stone Crushing Production Line Introduction

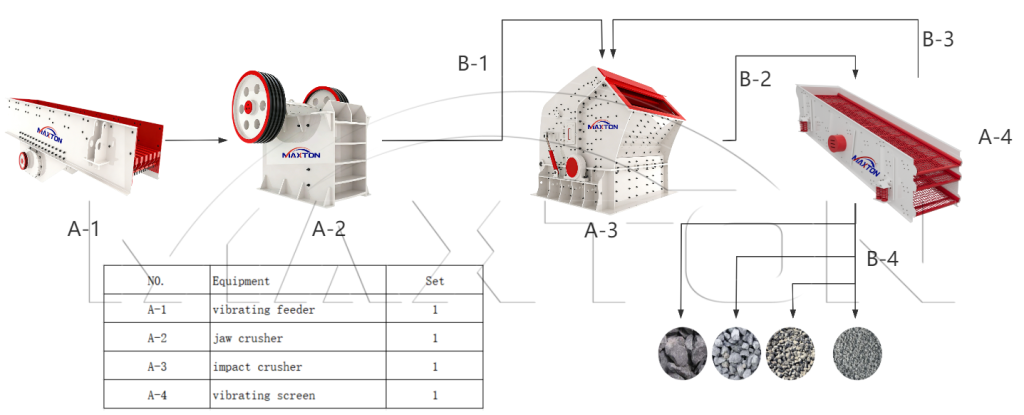

The core configuration of the 40-60 tons/hour stone crushing production line includes: a ZSW650×2500 vibrating feeder, a PE400×600 primary jaw crusher, a PF1007 impact crusher or a PEX250×1000 fine jaw crusher (secondary crushing optional), a YK1237 vibrating screen, a belt conveyor, and other supporting equipment.

This production line focuses on processing raw materials such as limestone, granite, and andesite, and can accurately produce various specifications of aggregates, covering coarse aggregate, crushed stone, rock sand, and fine aggregate. Coarse aggregate is widely used in the preparation of ready-mixed concrete and asphalt concrete; crushed stone is suitable for road construction base and subbase paving; and fine aggregate is used for concrete pouring and plastering material production.

Core Features of the 40-60 tph Stone Crushing Plant

1. Two-stage crushing process architecture: Based on the required fineness of the output, coarse crushing (primary crushing) and secondary crushing equipment are scientifically configured, ensuring an efficient and reasonable crushing process that guarantees the raw materials are refined to meet standards at each stage.

2. Diverse and Controllable Finished Product Specifications: Standard output particle sizes cover 0-6 mm (0-1/4 inch), 6-12 mm (1/4 inch-1/2 inch), and 12-25 mm (1/2 inch-1 inch). Other particle sizes can also be customized according to specific customer needs. The finished aggregate is of excellent quality and can be widely used in hydropower projects, highway construction, urban infrastructure, and many other fields.

3. Wide Range of Raw Material Compatibility: It can process a variety of rock and mineral raw materials such as limestone, granite, basalt, quartz, river pebbles, ballast, gold ore, iron ore, and andesite, adapting to the raw material endowments of different regions.

4. Flexible capacity options: In addition to the 50-ton/hour capacity, we can also customize and provide stone crushing production lines with capacities of 100 tons/hour, 150 tons/hour, 200 tons/hour, 300 tons/hour, 400 tons/hour, 500 tons/hour, 800 tons/hour, and 1000 tons/hour. We can provide customers with a customized solution including a production flow chart and detailed quotation free of charge.

Working Principle of 40-60 tons/hour Stone Crushing Plant

1. Raw Material Conveying and Pre-treatment: Large stones are fed into the primary jaw crusher via a vibrating feeder. A model with a screen can be selected to pre-separate smaller pieces, reducing costs and increasing efficiency.

2. Two-Stage Crushing: The coarsely crushed material is transferred by belt conveyor to the secondary crushing equipment (impact/fine jaw/cone crusher) for further refinement, ensuring precision.

3. Screening Output: The crushed material is graded by a vibrating screen to obtain finished products of 0-5mm, 5-10mm, 10-20mm, and 20-40mm, which can be stockpiled for sale or used in road construction, concrete projects, etc.