SOLUTION

300-450 tph Stone Crusher Plant

Processing Overview

The 300-450 TPH stone crushing plant is a core equipment solution for large-scale aggregate production projects, applicable to:

Major infrastructure: Highways, high-speed railways, key municipal engineering

Commercial aggregate yards and large-scale mining operations

Core competitiveness lies in scientific equipment matching: jaw crusher (primary crushing) + two cone crushers (secondary crushing), which ensures efficient, continuous and high-quality crushing to meet the massive aggregate demand of large projects.

300-450 tph Stone Crusher Plant Core Equipment: Primary and Secondary Crushing Systems

Applicable materials: Large-sized raw stones (max feed size 800-1500mm), including hard materials like granite, basalt, limestone

Crushing principle: Extrusion crushing

Core advantages: Simple structure, high reliability, large crushing capacity, low maintenance cost

Recommended models: PE 900×1200, PE 1000×1200 (for 300-450 TPH capacity)

Function: Stably crush raw stones into 150-200mm coarse materials, providing qualified feedstock for subsequent cone crushers

Crushing principle: Lamination crushing, suitable for hard materials (granite, basalt)

Product advantages: Uniform particle size, excellent grain shape, low needle-like particle content

Core role: Enhance secondary crushing efficiency and ensure production line stability

Configuration Merits: Parallel operation enables even distribution of coarse materials, avoiding single crusher overload. Common models: Two sets of CSB 160, HPC 220 or higher-capacity hydraulic cone crushers. Function: Jointly complete fine crushing to 20-40mm, meeting high-grade aggregate quality requirements.

Operational Flexibility: Adapts to slight production demand fluctuations by adjusting single cone crusher operation status, while ensuring product quality stability.

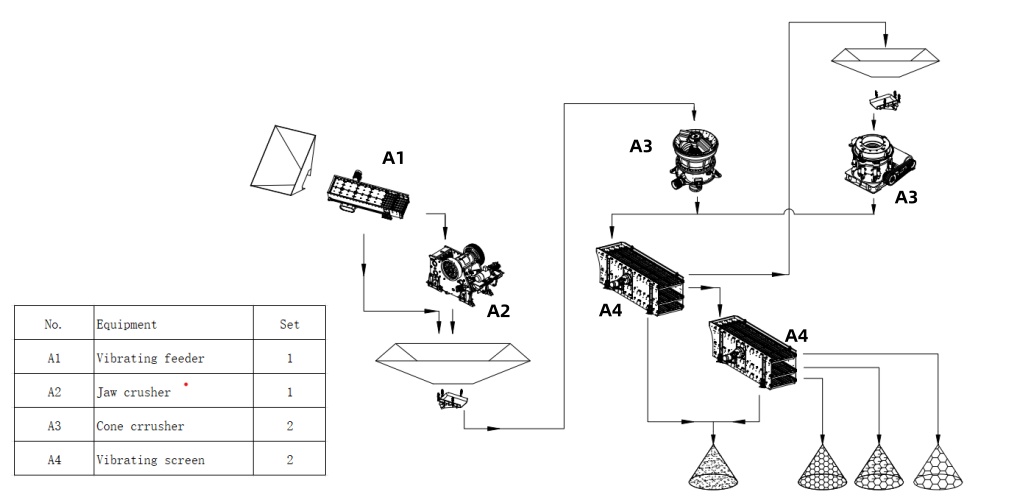

Operational Workflow Principle

The Stone Crushing Production Line adopts a closed-circuit circulation workflow, with clear steps as follows:

1. Feeding stage: Raw stones are conveyed to the vibrating feeder via belt conveyor; the feeder uniformly feeds materials into the jaw crusher to avoid uneven feeding-induced efficiency loss.

2. Secondary crushing stage: Coarsely crushed materials are transported to a distribution device, which evenly distributes them to two parallel cone crushers for fine crushing (ensuring optimal load for each crusher).

3. Classification & circulation: Crushed materials are sent to a high-efficiency vibrating screen for classification. Qualified products (meeting particle size requirements) are conveyed to the finished product stockpile; unqualified oversize materials are returned to cone crushers via return conveyor for re-crushing, forming a closed circuit.

Stone Crushing Production Line Advantages

1. High-Capacity Compatibility: Parallel operation of two cone crushers matches high-capacity jaw crusher output, ensuring stable 300-450 TPH production.

2. Modular Design: Facilitates installation, commissioning and relocation, suitable for large-scale construction site transfers.

3. Intelligent Control: Equipped with automated monitoring system for real-time operational status monitoring and remote adjustment, minimizing manual intervention.

4. Environmental Friendliness & Energy Efficiency: Integrated comprehensive dust and noise reduction system, complying with national environmental standards for green production.

Application Scenarios

– Large-scale infrastructure: Long-distance highways, high-speed railways, airports, large-span bridges

– Large-scale mining: Mineral crushing operations

– Commercial production: Large-scale aggregate production bases

– Resource recycling: Large-scale construction waste recycling projects (requiring high output and high-quality aggregates)

Conclusion

The 300-450 TPH stone crushing plant relies on the “jaw crusher + two parallel cone crushers” configuration, forming a high-efficiency, stable and high-capacity system. It fulfills large-scale project aggregate demand, guarantees finished product quality, and serves as a reliable solution for large-scale aggregate production.

We can provide a solution including flowcharts and quotations free of charge.