SOLUTION

200-300 tph Stone Crusher Plant

Processing Overview

A 200-300 tph stationary stone crushing plant is specifically designed for crushing rocks and minerals. It is typically built in a specific location and remains there for extended periods. This type of equipment is widely used in the mining, quarrying, construction, and recycling industries, and usually consists of jaw crushers, cone crushers, or impact crushers (sometimes including tertiary crushers), as well as screening machines, conveyors, and other equipment required for the crushing process.

200-300 tph Stone Crusher Plant Core Equipment: Primary & Secondary Crushing

1. Jaw Crusher (Primary Crushing):

As the first crushing link, it handles large raw stones (max feed size 600-1200mm, e.g., granite, basalt, limestone). Adopting extrusion crushing principle, it features simple structure, strong reliability and low maintenance cost.

Models like PE 750×1060/900×1200 stably reduce materials to 150-200mm, providing qualified feed for secondary crushing.

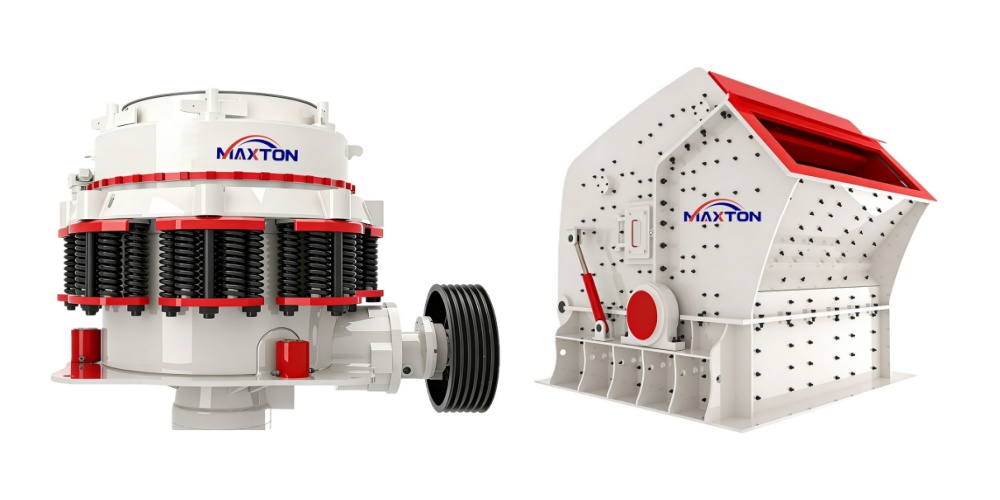

2.Cone/Impact Crusher (Secondary Crushing): The key to determining product quality, with two optional types for different needs:

Cone Crusher: Suitable for hard materials (granite, basalt). Lamination crushing ensures uniform particle size, good grain shape and low needle content. Models like CSB 160/HPC 220 match jaw crusher output well, ideal for high-quality aggregate requirements.

Impact Crusher: For medium-soft materials (limestone, dolomite). Impact crushing principle achieves large crushing ratio and cubic products, meeting commercial concrete/asphalt pavement needs. Easy to adjust discharge size for multi-spec products.

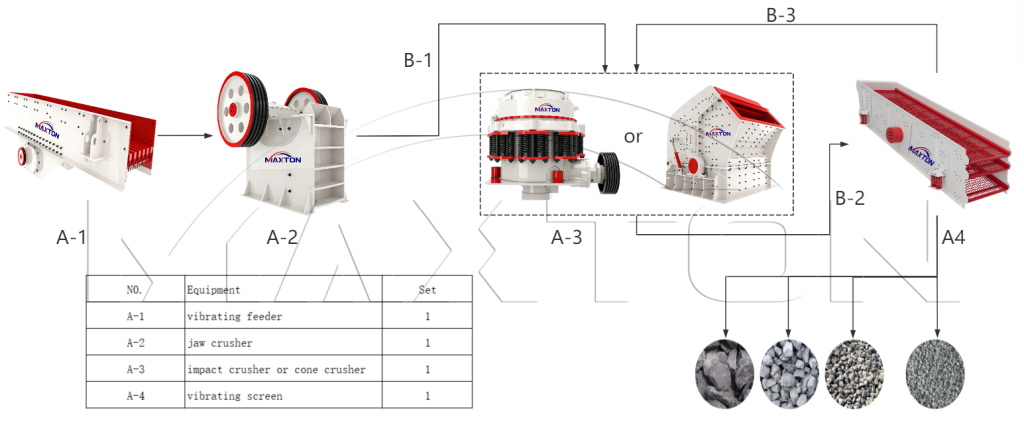

Workflow Principle

Firstly, raw stones are transported to the vibrating feeder by the conveyor belt, which uniformly feeds the materials into the jaw crusher (primary crushing) to avoid overload of the crusher.

Secondly, the coarsely crushed materials from the jaw crusher are conveyed to the cone crusher or impact crusher (secondary crushing) through the belt conveyor for fine crushing to meet the required particle size.

After secondary crushing, the materials are sent to the vibrating screen for classification: qualified products are transported to the finished product pile, while unqualified materials (too large particle size) are returned to the secondary crusher by the return conveyor for re-crushing, forming a closed-circuit circulation system.

Line Advantages & Applicable Scenarios

1.Applicable Scenarios: Infrastructure construction (highway, railway, airport), mining mineral crushing, commercial aggregate production, construction waste recycling.

2.High production efficiency, low cost, uniform particle size, good particle shape, and low dust content. An advanced control system ensures the safe and reliable operation of the entire stone crushing production line.

3.We also design and provide stone crushing production lines with capacities of 50 tons/hour, 100 tons/hour, 150 tons/hour, 200 tons/hour, 300 tons/hour, 400 tons/hour, 500 tons/hour, 800 tons/hour, and 1000 tons/hour. We can provide a solution including flowcharts and quotations free of charge.

In summary, the 200-300 TPH line relies on jaw crusher + cone/impact crusher configuration to form an efficient, stable system. Selecting the right secondary crusher based on raw materials and product requirements maximizes efficiency and quality, supporting engineering and industrial production.