SOLUTION

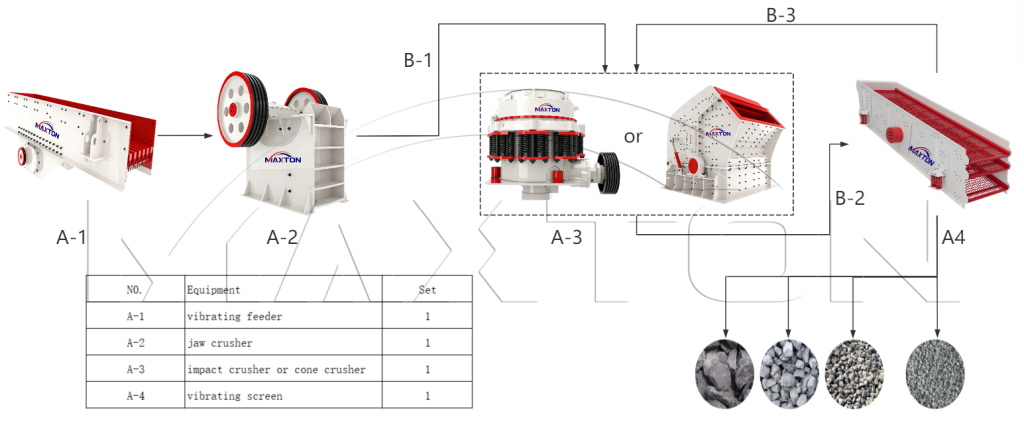

180-220 tph Stone Crushing Plant

Processing Overview

The 180-220 TPH stone crushing plant is a high-capacity, efficient system for large-scale aggregate production and hard stone processing.

With jaw crushers as primary crushing equipment and cone/impact crushers as optional secondary crushing, it integrates feeding, crushing, screening, conveying and dust removal functions.

Capable of processing granite, limestone, basalt and other raw materials, it provides high-quality aggregates for large infrastructure projects (highway, railway, urban rail transit, water conservancy, commercial concrete mixing stations).

Core Equipment Configuration

The 180-220 TPH stone crushing plant is built around jaw crushers and optional cone/impact crushers, matched with high-performance auxiliary equipment to form a systematic and efficient crushing process. Key configurations are as follows:

1. Jaw Crusher (Primary Crushing): As the core of primary crushing, it is responsible for breaking large-sized raw stones (maximum feeding size up to 800-1000mm) into small materials suitable for secondary processing.

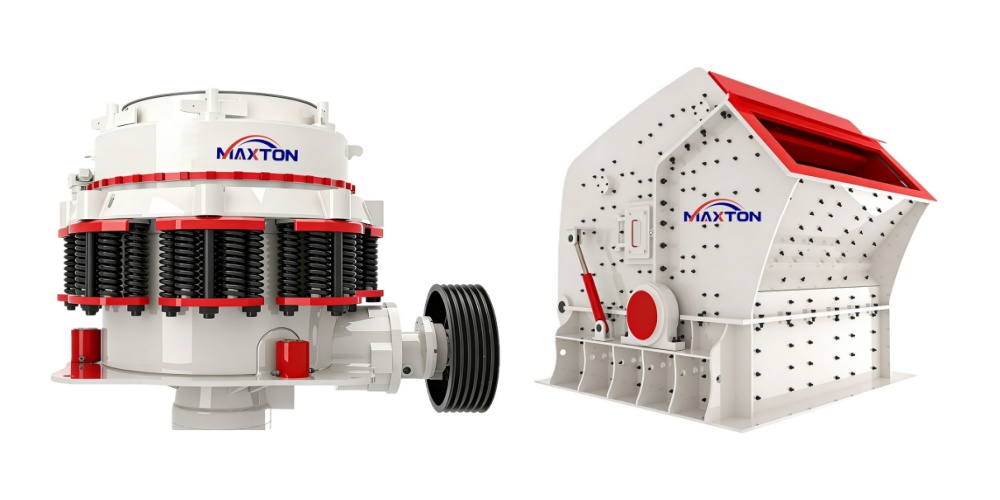

2. Secondary Crushing Equipment (Cone Crusher/Impact Crusher):

① Cone Crusher (for hard stone processing): Common models include CS series high-efficiency cone crushers, HP series hydraulic cone crushers. It has the advantages of uniform product particle size, good cubical shape, low needle-like content and high crushing efficiency, suitable for processing granite, basalt and other high-hardness stones.

② Impact Crusher (for medium-hard stone and shape-demanding products): Common models include PFW series impact crushers. It adopts impact crushing principle, producing products with excellent particle shape and high crushing ratio, suitable for limestone, dolomite and other medium-hard materials, and ideal for projects requiring high-quality aggregate shape.

3. Auxiliary Equipment: Including vibrating feeder, vibrating screen (accurately grading finished products of 0-5mm, 5-10mm, 10-20mm, 20-40mm, etc.), heavy-duty belt conveyors, hopper, and high-efficiency pulse dust collector.

Key Advantages of the 180-220 tph Stone Crushing Plant

1. High-Capacity & Stable Output: Scientific combination of large jaw crusher and high-efficiency secondary crusher realizes rational two-stage crushing division. Stable output of 180-220 TPH fully meets large infrastructure material needs.

2. Flexible Secondary Crushing Options: Customers can choose cone/impact crusher based on raw material hardness (hard/medium-hard) and product requirements (shape, fineness), greatly improving scenario adaptability.

3. Energy-Saving & Environmental Protection: Core equipment adopts energy-saving motors and optimized structures to reduce unit energy consumption.

Working Process

Feeding & Preliminary Screening: Large raw stones are transported to hopper by loader, then uniformly fed into jaw crusher by vibrating feeder, which pre-removes soil and fine debris.

Primary Crushing: Jaw crusher crushes large stones into 150-250mm materials through extrusion, which are transported to secondary crushing equipment (cone/impact crusher) by heavy-duty belt conveyor.

Secondary Crushing: Cone/impact crusher refines materials according to preset fineness—cone crusher for hard stones, impact crusher for medium-hard stones.

Screening & Circulation Crushing: Crushed materials are graded by vibrating screen. Qualified products go to finished product yards; oversize materials are returned to secondary crusher for re-crushing, avoiding raw material waste.

Application Scenarios

With high capacity, flexible configuration and excellent quality, the plant is widely used in large projects:

1. Large infrastructure (high-grade highways, high-speed railways, urban viaducts, airports);

2. Water conservancy projects (large reservoirs, dams);

3. Building construction (large commercial concrete mixing stations, prefabricated component factories);

4. Mining industry (crushing metal/non-metallic ores in medium-large mines).

The 180-220 tph Stone Crushing Plant with jaw and optional cone/impact crushers provides strong support for large-scale aggregate production and project construction.