SOLUTION

100-150 tph Stone Crusher Plant

Processing Overview

100-150 TPH Stone Crusher Plant: Efficient Crushing Solution with Jaw & Cone Crushers

The 100-150 TPH (Tons Per Hour) stone crusher plant is a high-performance crushing system specifically designed for processing various hard stones such as granite, limestone, basalt, andesite, and river pebbles.

Centered on jaw crushers and cone crushers as the core crushing equipment, this plant integrates feeding, crushing, screening, and conveying functions, providing high-quality aggregates for infrastructure projects including highway construction, railway laying, urban infrastructure, water conservancy projects, and commercial concrete production.

With its stable operation, high production efficiency, and excellent product quality, it has become a preferred choice for medium-scale aggregate production enterprises.

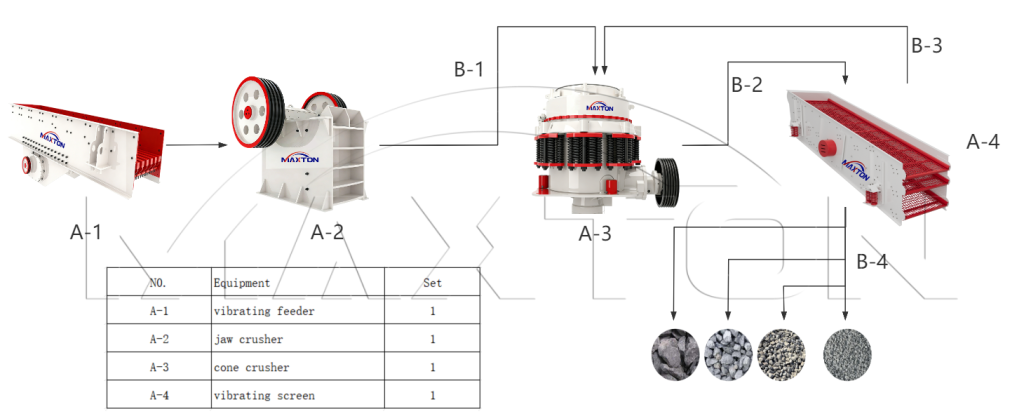

Core Equipment Configuration

Centered on jaw and cone crushers, the 100-150 TPH stone crusher plant is equipped with professional auxiliary equipment to form an efficient crushing system. Key configurations are as follows:

1. Jaw Crusher (Primary Crushing): Responsible for breaking large raw stones (max feeding size 600-800mm) into processable small materials.

Common models: PE 600×900, PE 750×1060.

Features: strong crushing capacity, simple structure, reliable operation, suitable for hard and brittle materials.

2. Cone Crusher (Secondary Crushing): Refines materials from jaw crusher.

Optional models: PYB, PYZ, CS series.

Advantages: uniform particle size, good particle shape, high efficiency. Equipped with hydraulic adjustment and protection for easy discharge port adjustment and equipment safety.

3. Auxiliary Equipment: ZSW vibrating feeder (uniform feeding & pre-screening impurities), vibrating screen (grading finished products like 0-5mm, 5-10mm), belt conveyor (material transportation), hopper and dust removal equipment (meeting environmental standards).

Key Advantages of the Plant

1. High Crushing Efficiency & Stable Output:

The combination of jaw crusher and cone crusher realizes the scientific division of labor in two-stage crushing. The jaw crusher efficiently completes the primary crushing, and the cone crusher performs precise secondary crushing, which greatly improves the overall crushing efficiency. The plant’s output can stably reach 100-150 tons per hour, meeting the production needs of medium-scale projects.

2. Excellent Product Quality:

The cone crusher adopts a layered crushing principle, which makes the crushed materials have uniform particle size, good particle shape (cubical), and low needle-like content, fully meeting the quality requirements of building aggregates. The finished products can be widely used in high-grade highways, bridges, and other key projects with strict quality requirements.

3. Strong Adaptability to Raw Materials:

The plant is suitable for processing various hard stones and ores with compressive strength up to 320MPa, such as granite, basalt, limestone, river pebbles, and iron ore. It can adapt to different types of raw material conditions and meet the diverse production needs of customers.

The working process of the 100-150 TPH stone crusher plant is systematic and efficient, and the specific steps are as follows:

1. Feeding & Preliminary Screening:

Large-sized raw stones are transported to the hopper by a loader, and then uniformly fed into the jaw crusher by the vibrating feeder. During the feeding process, the vibrating feeder can pre-screen the raw materials to remove soil and fine debris, ensuring the purity of the materials entering the crusher.

2. Primary Crushing:

The jaw crusher crushes the large raw stones into small-sized materials (generally 100-200mm) through the extrusion and crushing of the fixed jaw and the movable jaw, and the crushed materials are transported to the cone crusher by the belt conveyor.

3. Secondary Crushing:

The cone crusher further refines the materials transported by the belt conveyor. According to the required fineness of the finished product, the discharge port size is adjusted to obtain materials that meet the screening requirements.

4. Screening & Circulation Crushing:

The materials after secondary crushing are transported to the circular vibrating screen for grading. The materials that meet the specified particle size are transported to the finished product yard as qualified finished products; the materials that do not meet the particle size requirements are transported back to the cone crusher by the return belt conveyor for re-crushing until they meet the standards.

Application Scenarios

The 100-150 TPH stone crusher plant is widely used in various fields due to its excellent performance and stable output:

1. Infrastructure construction: Used for producing aggregates for highways, railways, airports, bridges, and urban roads;

2. Building construction: Providing high-quality concrete aggregates for commercial concrete mixing stations and prefabricated component factories;

3. Water conservancy projects: Used in the construction of reservoirs, dams, and irrigation channels;

4. Mining industry: Used for the crushing of metal ores and non-metal ores in medium-scale mines.

In addition, we can provide customized design services according to the customer’s specific needs (such as raw material type, finished product specification, and site conditions), and provide a complete set of solutions including process flow diagrams, equipment lists, and detailed quotations for free. The 100-150 TPH stone crusher plant with jaw crusher and cone crusher as the core will bring efficient and reliable production support to your aggregate production business.